Tube bending machine - Turbo Service Belgrade (2013)

The machine is based on PLC controller Schneider Electric M238 and two servo axes. On the basis of the given parameters on the operator panel, the machine bends metal profiles using an innovative bending method.

Machine for automatic welding - Prim Kostolac (2014)

The automatic welding machine is based on PLC controller Schneider Electric M238 and has 3 linear axes with stepping motors and one rotary axis controlled by a frequency converter. On the basis of the entered parametars, the machine can weld flat surfaces and make a circular welding.

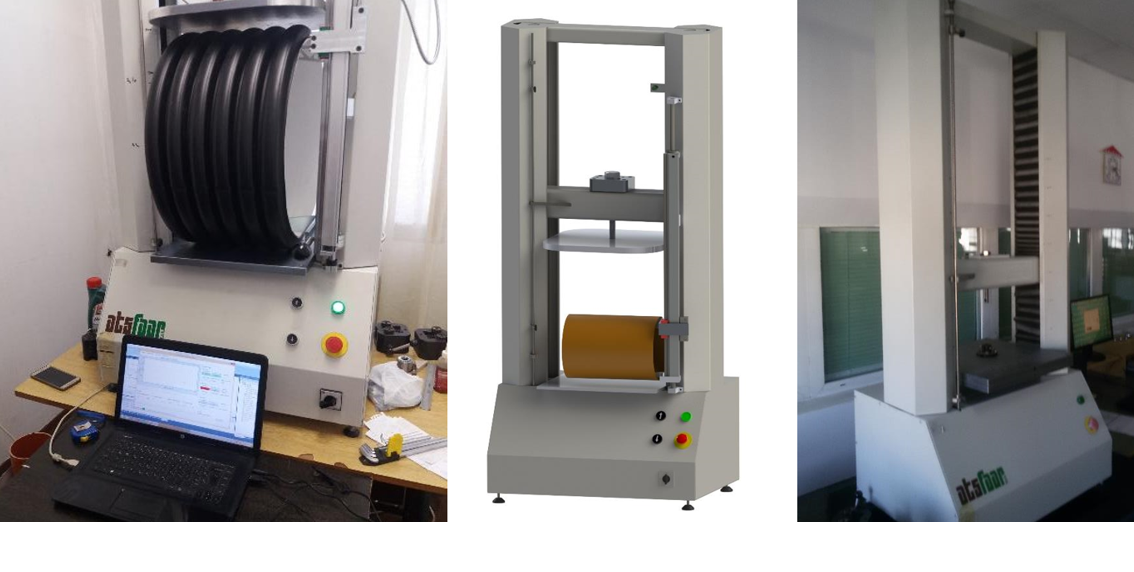

Impact test machine – Impact2000 – Peštan d.o.o Aranđelovac (2016)

The Impact test machine “Impact2000” is designed for testing of PVC pipes and fittings to determine the impact strength of the same products. The impact test machine is based on standard PLC controller and HMI. It has two axis, one with variable frequency drive for adjustment of V block height, and servo axis for lifting the weight to reference height according to standards requirement.

Machine for determination of pipe tensile properties – SKAZ2000 – Peštan d.o.o Aranđelovac (2018)

The machine is based on a microcontroller and a computer application. Real-time measurements of force and length are performed, and after completion of the test, the application generates a laboratory report.

Automatization of hydraulic presses for drilling process – Unipromet d.o.o Čačak (2019)

The automation of the drilling process on the production line for the production of a 3 waves steel protective fences is based on the Siemens PLC controller series S1200. Drilling is based on 8 presses with special tools.

Automatization of production line for C profiles – Unipromet d.o.o Čačak (2019)

The machine is based on PLC controller Schneider Electric M238 and two servo axes. On the basis of the given parameters on the operator panel, the machine bends metal profiles using an innovative bending method. The automation is based on the Siemens PLC controller series S1500T. The automatic line has 2 servo axes, flying drilling and flying cutting, implemented using the Siemens servo driver series S120. The main drive of the line is based on a DC motor with power of 98kW, which is controlled via Siemens DC converter. The line is based on the Profinet protocol and has about 40 devices that communicates. The electric project and the creation of the electric cabinets is the work of the company Enel d.o.o.